High carbon (titanium) fiber brake pads

High carbon (titanium) fiber is a brake pad used in high-end vehicles, which is rarely seen on the market now. Carbon (titanium) fiber is an upgraded version of ceramic chips. Lightweight, high strength, low coefficient of thermal expansion, good thermal conductivity, good heat resistance, etc. Carbon fiber has good curve stability, low thermal shock on the friction surface, and wear resistance that is more than 1.5 times that of ordinary ceramic tiles.

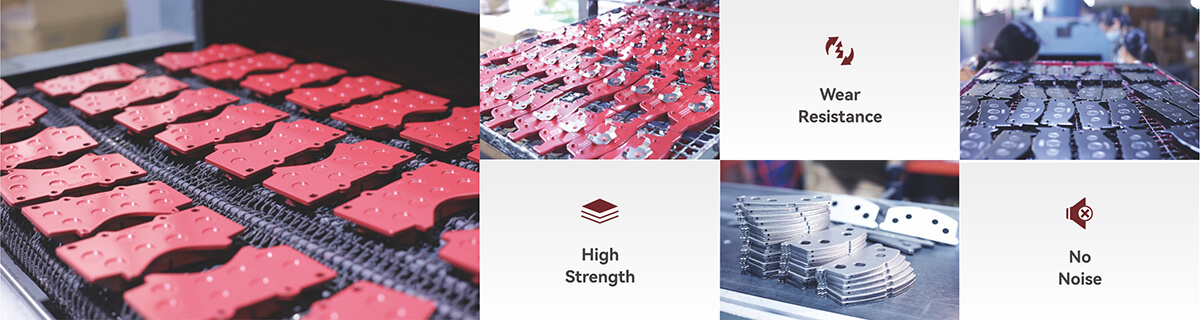

Ceramic brake

Ceramic brake pads can be said to make up for the shortcomings of existing models and semi metal brake pads. Its material is mainly composed of various materials such as mineral fibers, aramid fibers, and ceramic fibers. On the one hand, due to the lack of metal material, the noise will be significantly reduced when there is friction between brake pads and brake discs. At the same time, the friction process will significantly reduce the damage to the brake disc.

In addition, ceramic brake pads can maintain a stable friction coefficient at high temperatures, avoiding the attenuation of braking force caused by material melting during long-term or high-speed braking of organic or metal brake pads, greatly improving safety, and also being more wear-resistant.